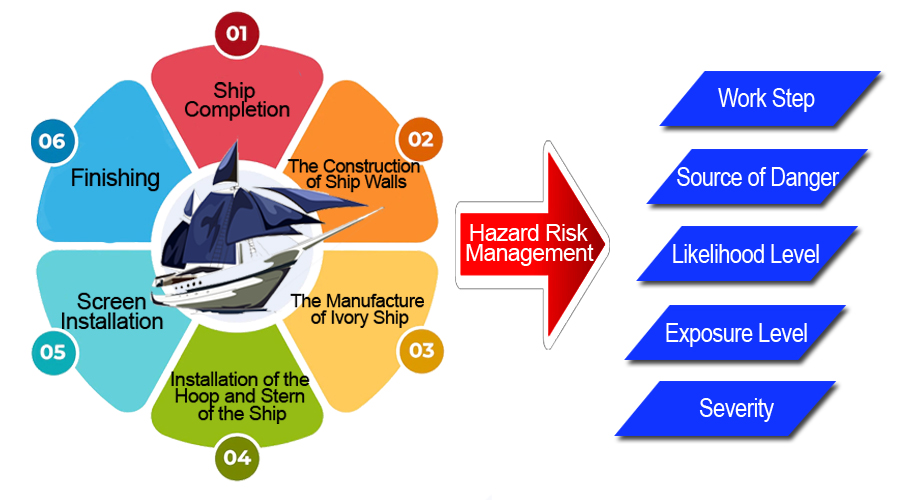

Hazard Risk Management for Occupational Safety and Health on Phinisi Shipbuilding

Abstract

The implementation of the making process of a Phinisi ship has a potential hazard impact on occupational safety and health, including the tools, materials, and work processes respectively. One of the accident risk management methods used is called the Hazard and Operability method, which reviews the process of making a Phinisi ship in order to identify some hazards and analyze the risk of work accidents. The purpose of this study was to use hazard and operability (HAZOP) to assess the level of occupational health and safety risk for Phinisi ship workers. This research was quantitative with a descriptive approach because it described the risk of work accidents in making Phinisi Ships. The population in this study were all Phinsi ship workers, whilst the sampling technique was total sampling. The results showed that the hazards identified in the Phinisi shipbuilding process were physical, chemical, physiological, and mechanical hazards. The most dominant hazard identified in each work step process was a physical hazard. At the stage of making ivory or ship hulls, there was a very high level of possible risk. In addition, at the work step of installing ship sails, the severity of the risk was very serious. This study led to a systematic evaluation of the possible risks and a suggestion for how industrial managers can reduce the risks that come up when building ships.

Downloads

References

Badri, A., Gbodossou, A., & Nadeau, S. (2012). Occupational health and safety risks: Towards the integration into project management. Safety science, 50(2), 190-198. https://doi.org/10.1016/j.ssci.2011.08.008

de la O Herrera, M. A., Luna, A. S., da Costa, A. C. A., & Lemes, E. M. B. (2015). A structural approach to the HAZOP–Hazard and operability technique in the biopharmaceutical industry. Journal of Loss Prevention in the Process Industries, 35, 1-11. https://doi.org/10.1016/j.jlp.2015.03.002

Efe, B. (2019). Analysis of operational safety risks in shipbuilding using failure mode and effect analysis approach. Ocean Engineering, 187, 106214. https://doi.org/10.1016/j.oceaneng.2019.106214

Fragiadakis, N. G., Tsoukalas, V. D., & Papazoglou, V. J. (2014). An adaptive neuro-fuzzy inference system (anfis) model for assessing occupational risk in the shipbuilding industry. Safety Science, 63, 226-235. https://doi.org/10.1016/j.ssci.2013.11.013

Fridayanti, N. M. A., Mertaningrum, N. L. P. E., & Merta, I. N. (2021). Pemberdayaan Jaminan Sosial Ketenagakerjaan (BPJS) Pada Perusahaan Yang Dikelola Oleh Pihak Swasta. Jurnal Ilmu Sosial dan Ilmu Politik, 72-89. https://doi.org/10.52318/jisip.2021.v35.2.2

International Labour Organization (2018). Meningkatkan Keselamatan dan Kesehatan Pekerja Muda. Jakarta, Kantor Perburuhan Internasional. https://www.ilo.org/jakarta/whatwedo/publications/WCMS_627174/lang--en/index.htm

Ishtiaque, S., Sikandar, S., Akhter, M. F., Altaf, M., & Siddique, M. (2019). Hazard and Operability Analysis (HAZOP) of a Plastic Manufacturing Plant at Karachi, Pakistan. Journal of Applied and Emerging Sciences, 9(1), pp-1. http://dx.doi.org/10.36785/jaes.91264

Khamidi, M. F., Rochani, I., & Chamelia, D. M. (2015). Hazard and operability analysis (HAZOP) of mobile mooring system. Procedia Earth and Planetary Science, 14, 208-212. https://doi.org/10.1016/j.proeps.2015.07.103

Kim, K. W., Park, S. J., Lim, H. S., & Cho, H. H. (2017). Safety climate and occupational stress according to occupational accidents experience and employment type in shipbuilding industry of korea. Safety and health at work, 8(3), 290-295. https://doi.org/10.1016/j.shaw.2017.08.002

Kotek, L., & Tabas, M. (2012). HAZOP study with qualitative risk analysis for prioritization of corrective and preventive actions. Procedia Engineering, 42, 808-815. https://doi.org/10.1016/j.proeng.2012.07.473

Kurniasari, A. (2017). Analisis Ergonomi Pada Kapal Selam Mini (Doctoral dissertation, Institut Teknologi Sepuluh Nopember). https://repository.its.ac.id/3779/

Lee, J., & Lee, D. K. (2018). Application of industrial risk management practices to control natural hazards, facilitating risk communication. ISPRS International Journal of Geo-Information, 7(9), 377. https://doi.org/10.3390/ijgi7090377

Mardatillah, N. I. (2021). Identifikasi Potensial Hazard dan Analisis Risiko K3 dengan Metode Job Safety Analysis (JSA) pada Panrita Lopi Pinisi Bulukumba Tahun 2021 (Thesis, Universitas Islam Negeri Alauddin Makassar). http://repositori.uin-alauddin.ac.id/20310/

Noriyati, R. D., Rozaaq, W., Musyafa, A., & Soepriyanto, A. (2015). Hazard & operability study and determining safety integrity level on sulfur furnace unit: A case study in fertilizer industry. Procedia Manufacturing, 4, 231-236. https://doi.org/10.1016/j.promfg.2015.11.036

Permana, S. D., & Handayani, H. (2022). Analisis Kecelakaan Kerja Dengan Perilaku Pekerja Di Area Galangan Kapal. Jurnal Mahasiswa BK An-Nur: Berbeda, Bermakna, Mulia, 8(2), 80-84. https://ojs.uniska-bjm.ac.id/index.php/AN-NUR/article/view/7108

Pradipta, R. A. (2016). Risk Assessment pada Pekerjaan Menebang Kayu di Hutan Produksi (Studi Kasus pada Pengoperasian Chainsaw Perum Perhutani KPH Madiun). The Indonesian Journal of Occupational Safety and Health, 5(2), 153-162. http://dx.doi.org/10.20473/ijosh.v5i2.2016.153-162

Reniers, G. (2017). On the future of safety in the manufacturing industry. Procedia manufacturing, 13, 1292-1296. https://doi.org/10.1016/j.promfg.2017.09.057

Sangaji, J., Jayanti, S., & Lestantyo, D. (2018). Faktor-faktor yang berhubungan dengan perilaku tidak aman pekerja bagian lambung galangan kapal PT X. Jurnal Kesehatan Masyarakat (Undip), 6(5), 563-571. https://doi.org/10.14710/jkm.v6i5.22095

Sengupta, A., Bandyopadhyay, D., Van Westen, C. J., & Van Der Veen, A. (2016). An evaluation of risk assessment framework for industrial accidents in India. Journal of loss prevention in the process industries, 41, 295-302. https://doi.org/10.1016/j.jlp.2015.12.012

Simanjuntak, R. A., & Abdullah, R. (2018). Tinjauan Sistem dan Kinerja Manajemen Keselamatan & Kesehatan Kerja Tambang Bawah Tanah CV. Tahiti Coal, Talawi, Sawahlunto, Sumatera Barat. Bina Tambang, 3(4), 1536-1545. http://ejournal.unp.ac.id/index.php/mining/article/view/102260

Takala, J., Hämäläinen, P., Saarela, K. L., Yun, L. Y., Manickam, K., Jin, T. W., & Lin, G. S. (2014). Global estimates of the burden of injury and illness at work in 2012. Journal of occupational and environmental hygiene, 11(5), 326-337. https://doi.org/10.1080/15459624.2013.863131

Thiede, I., & Thiede, M. (2015). Quantifying the costs and benefits of occupational health and safety interventions at a Bangladesh shipbuilding company. International journal of occupational and environmental health, 21(2), 127-136. https://doi.org/10.1179%2F2049396714Y.0000000100

Tjendera, M., Aulia, A., Aladin, A. (2018). Hubungan Kelelahan Kerja dengan Kejadian Kecelakaan Kerja pada Pekerja Galangan Kapal. Jurnal Kesmas Dan Gizi (JKG), 1(1), 58-67. https://doi.org/10.35451/jkg.v1i1.106

Tsoukalas, V. D., & Fragiadakis, N. G. (2016). Prediction of occupational risk in the shipbuilding industry using multivariable linear regression and genetic algorithm analysis. Safety Science, 83, 12-22. https://doi.org/10.1016/j.ssci.2015.11.010

Wulandari, D. (2017). Risk Assessment Pada Pekerja Pengelasan Perkapalan Dengan Pendekatan Job Safety Analysis. The Indonesian Journal of Occupational Safety and Health, 6(1), 1–15. https://doi.org/10.20473/ijosh.v6i1.2017.1-15

Yuliani, U. (2017). Manajemen Risiko Keselamatan dan Kesehatan Kerja (K3) Pada Infrastruktur Gedung Bertingkat. Jurnal Ilmiah Desain & Konstruksi, 16(1). https://ejournal.gunadarma.ac.id/index.php/dekons/article/view/1696

Yusuf, M., Idris, M. F., & Nur, M. B. (2019). Manajemen Risiko Keselamatan dan Kesehatan Kerja pada Pekerjaan Galangan Kapal di Tanjungpinang. Jurnal Kesehatan, 12(2), 260-272. https://doi.org/10.32763/juke.v12i2.172

Copyright (c) 2022 Hasbi Ibrahim, Kiky Afriani Andi Aris

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

Authors are permitted to publish their work online in third parties as it can lead to wider dissemination of the work.